About us

CIR-Q-Tech: Leading Provider of ESD Control Solutions

Cir-Q-Tech Engineering was intercepted in the year 1989 with the objective to manufacture and market Quality products for the Electronics Manufacturing Industries, including, Soldering related equipment and ESD control products. The company achieved good recognition in the industry through product innovation and quality of services rendered to far-flung customers, leading to reduction in losses due to Electrostatic Discharge.

Read moreServices

Ionization in Pharma

Principle of static electricity

When looking closely, you can see that all matter is composed of atoms. An atom has protons and electrons that are in electrical balance. Electrons may become separated from or attached to the atom with a small force.

Disruption of the balance between protons and electrons leads to static electricity. Charge generation will occur when two surfaces in contact are rubbed or separated. One surface loses electrons and becomes positively charged while the other surface gains the same electrons and becomes negatively charged.

Electrostatic charges generated during powder handling often adversely influence process performance. In cases where significant charges are present, accidental discharge of the accumulated static charges may cause sparks, fires, even explosions, affecting process performance and causing significant safety concerns. Powder processing operations can generate vast quantities of electrostatic charge via the movement of powder.

Electrostatic charging is a complicated phenomenon, especially when handling powder mixtures. The standard method of charging on powder processing operations is due to the contact and separation of the powder with processing equipment, the powder particles colliding between themselves (or both).

For instance, the charged particles in pneumatic transport lines or in fluidized beds experience electrostatic forces and tend to adhere to the walls. If the particles are excessively charged, electrostatic discharge may occur, posing a risk of fire and explosions.

Removing static electricity with ionizers

Conductive materials can discharge static electricity immediately with grounding. When surface treatments such as anodization and the like are applied, conductive materials will become insulated and grounding will be ineffective.

Insulated materials cannot discharge static electricity even if they are grounded. To discharge static electricity, you will need a suitable ionizer system as explained below:

Air Ionization

An ion is an atom that is electrically charged. It is produced when there is a change in the electrical balance of a neutral atom. If the outer shell of an atom takes on an extra electron, an ion with a negative charge is formed. If the outer shell loses an electron, a positive ion is formed.

When high voltage is applied on the tip of the ion emitter, corona discharge is observed which breaks the air molecules into + and – ions. These ions can be carried by air & used to safely neutralize the static charge which may be building up in powder processing applications.

Whatever static charge is present on objects in the work environment will be reduced and neutralized by attracting opposite polarity charges from the air.

We are happy to present to you, the solutions for the most difficult static charge problems. These are developed by SIMCO-ION, USA (the world’s most experienced company in ionization, founded 85 years ago) & proudly implemented by CIR-Q-TECH TAKO TECHNOLOGIES Pvt Ltd(pronounced Circuit-Tech Tako), the first & foremost company in the field of electrostatics in India, founded 30 years ago. The combined expertise of these two companies means that the most complicated static charge problems now have simple, easy to install solutions.

The IQ Power HL System is our most innovative static control system designed to optimize static neutralization in hazardous locations where safety is a concern. The IQ Power HL ensures exceptional ionization performance within Class1, Div. 1, Group D classified areas.

The IQ HL Static Neutralizing Bar is highly efficient and built for long lasting durability with little maintenance. Each individual ion emitting pin is current limited to eliminate the risk of hazardous electrical shock and explosion in specific classified areas. All normal (or otherwise) working conditions are continuously monitored & reported for peace of mind.

- Straight and flanged edges available.

- Simple replacement sizes provided as per your existing air duct.

- No modification required on the FBD machine.

- No modification to existing process.

- Simple Installation, less downtime needed for installation.

- SS304/SS316 or other grades of Stainless Steel can be provided.

NOTE : Complete solutions also available for all kinds of pharma powder process operations like SIFTERS, AIR JET MILLING, AIR/VACUUM TRAY DRYING, POWDER STORAGE AREAS ETC.

Air Jet Milling Sifter

ESD Consultancy & Training

Often we know by experience that its not just enough to have good products. Its also important to have the relevant knowledge & training on how to properly utilize all the products as per the relevant ESD standards. CIRQTECH has managed to achieve the distinction of becoming the leader of the ESD industry by offering complete consultation ,training, audit services with the relevant products. By offering the full spectrum of technical knowledge with the highest quality products, we have been able to win & retain the trust of our customers. Our highly qualified team is able to understand the technical problems faced in every day practical situations. For more details Click here

We have won appreciation from customers in various industries by being able to solve persistent, nagging problems in manufacturing processes. We would like to draw your attention to case studies from different industries

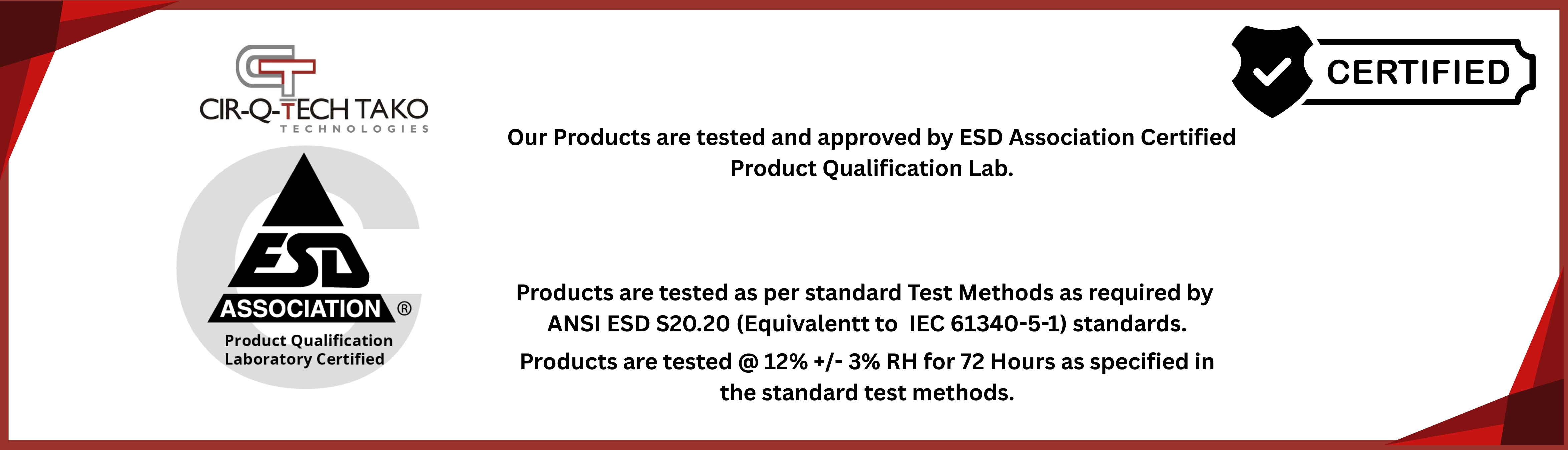

ESD Testing Lab

A state of the art testing lab which tests products to make sure they qualify as per the relevant ESD standards.

We possess highly accurate instrumentation (traceable to national standards) for all our testing.

Professional Installation

We offer professional installation service for all products sold by us. Our installation team is experienced in installing ESD flooring, furniture & ionization for hundreds of successful projects. We are able to setup the complete infrastructure required for ESD labs & certify the products as per the ESD standards.

We also offer complete maintenance & floor care to make sure that the critical ESD flooring is ensured long life over many years of usage.

Custom Design

While our standard designs have gained enduring popularity among a large range of customers, we understand that there are always special requirements. For this reason, our experienced design team also offers deep customization options, subject to specific quantity.

Our design team would discuss with the customer on all relevant aspects such as :

Size requirement

Load bearing capacity

Work flow within the lab area

Accessories required as well as their specific placement based on work flow

Attention to ergonomics

Entire lab layout & placement of workstations for optimum space utilization.

INFRASTRUCTURE

Cir-Q-Tech Tako Technologies, a pioneer in comprehensive ESD Control solutions, was established in the year 1989, with an objective to manufacture and market quality& Control products for a wide range of manufacturing industries